Improving Efficiency with Sanitary Pigging System

A sanitary pigging system is a crucial technology for industries that require high levels of hygiene and efficiency. This system is used to recover valuable liquid products, clean pipelines, and reduce waste in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. By ensuring thorough pipeline cleaning and product recovery sanitary pigging system enhances production efficiency, minimizes contamination risks, and reduces operational costs. This article explores the functionality, benefits, applications, and advancements of sanitary pigging systems.

What Is a Sanitary Pigging System?

A sanitary pigging system is a specialized technology designed to clean and recover liquids from pipelines while maintaining the highest hygiene standards. The system utilizes a cleaning device known as a “pig” that travels through the pipeline, pushing residual product toward the processing or filling unit. Unlike traditional industrial pigging systems, sanitary pigging systems are designed with FDA-approved materials, food-grade seals, and automated cleaning mechanisms to ensure compliance with stringent hygiene requirements.

This technology plays a vital role in industries where liquid products must be handled with precision and cleanliness. It allows manufacturers to maximize product utilization while ensuring contamination-free operations.

How Does a Sanitary Pigging System Work?

A sanitary pigging system operates through a systematic process involving multiple steps:

- Pig Launching – The pig is inserted into the pipeline using a pig launcher.

- Pig Propulsion – The pig moves through the pipeline, propelled by compressed air, gas, or liquid pressure.

- Product Recovery – The pig pushes out residual liquid, reducing waste and ensuring maximum product utilization.

- Pig Collection – The pig reaches the receiver, where it is removed and sanitized for reuse.

- Automated Cleaning – After pigging, the pipeline is flushed and sanitized using Clean-in-Place (CIP) or Sterilize-in-Place (SIP) systems to ensure complete hygiene.

This process ensures that pipelines remain free from contamination, allowing manufacturers to maintain high product quality standards.

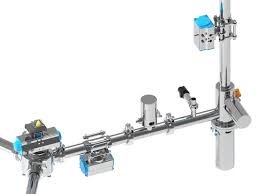

Key Components of a Sanitary Pigging System

A sanitary pigging system consists of several essential components designed for hygienic operations:

- Sanitary Pig: A flexible or solid device made from FDA-approved materials that effectively pushes product through pipelines.

- Pig Launcher: A chamber where the pig is introduced into the system.

- Pig Receiver: A collection unit that captures the pig after it has completed its journey.

- Pipeline System: Stainless steel pipelines with smooth interiors that meet sanitary standards.

- Automated Control System: A programmable system that regulates pig movement and cleaning cycles.

- CIP and SIP Mechanisms: Automated cleaning and sterilization systems to maintain hygiene.

Each of these components plays a crucial role in ensuring the sanitary pigging system functions efficiently and meets regulatory requirements.

Benefits of Using a Sanitary Pigging System

1. Maximizing Product Recovery

One of the primary advantages of a sanitary pigging system is its ability to recover up to 99% of residual product in pipelines. This reduces waste, minimizes product loss, and improves overall yield.

2. Maintaining High Hygiene Standards

Sanitary pigging systems ensure that pipelines are free from contamination, making them ideal for industries with strict hygiene requirements such as food, pharmaceuticals, and cosmetics.

3. Reducing Cross-Contamination

In multi-product manufacturing environments, sanitary pigging prevents cross-contamination between different product batches, reducing the risk of product recalls.

4. Lowering Water and Chemical Usage

Traditional pipeline cleaning methods require significant amounts of water and cleaning chemicals. A pigging system minimizes these requirements, leading to cost savings and environmental benefits.

5. Improving Operational Efficiency

By eliminating long cleaning cycles and reducing downtime, a sanitary pigging system enhances production efficiency and allows faster product changeovers.

6. Extending Equipment Life

Regular use of harsh cleaning chemicals can damage pipelines and equipment over time. Pigging provides a non-abrasive cleaning method that helps extend the lifespan of processing equipment.

Industries That Use Sanitary Pigging Systems

Sanitary pigging systems are widely used in industries that require strict hygiene and efficiency. Some of the key industries that benefit from this technology include:

Food and Beverage Industry

- Dairy products such as milk, yogurt, and cream

- Juices, soft drinks, and syrups

- Sauces, dressings, and condiments

- Beer, wine, and spirits

Pharmaceutical Industry

- Liquid medications and syrups

- High-value pharmaceutical ingredients

- Biotech formulations

Cosmetics and Personal Care Industry

- Shampoos, conditioners, and lotions

- Liquid soaps and body washes

- Essential oils and perfumes

Chemical Industry

- Food-grade additives and colorants

- Sanitary-grade coatings and solvents

By implementing sanitary pigging systems, these industries can improve product recovery, enhance hygiene, and streamline production processes.

Considerations for Implementing a Sanitary Pigging System

While sanitary pigging systems offer numerous benefits, proper planning is essential for successful implementation. Some key considerations include:

- Pipeline Compatibility – Ensure that the existing pipeline system is compatible with pigging technology and meets sanitary standards.

- Material Selection – Use FDA-approved materials to prevent contamination and maintain hygiene.

- Automation and Monitoring – Integrate advanced control systems to optimize pigging operations and ensure efficiency.

- Cleaning and Maintenance – Regularly inspect and sanitize the system to maintain peak performance.

By addressing these factors, manufacturers can maximize the effectiveness of their sanitary pigging system.

Challenges of Sanitary Pigging Systems

Despite their advantages, sanitary pigging systems also present certain challenges:

- High Initial Investment – The cost of installing a sanitary pigging system can be significant, but the long-term savings in product recovery and reduced cleaning costs outweigh the initial expense.

- System Integration – Existing pipelines may require modifications to accommodate pigging technology, which can be time-consuming.

- Operator Training – Staff must be trained to operate and maintain the pigging system correctly.

Future Developments in Sanitary Pigging Technology

As technology advances, sanitary pigging systems continue to evolve. Some anticipated developments include:

- Smart Pigging Systems – Incorporating IoT sensors for real-time monitoring and predictive maintenance.

- Increased Automation – Fully automated pigging systems integrated with Industry 4.0 technologies for enhanced efficiency.

- Eco-Friendly Solutions – Development of pigging systems that further reduce water and chemical usage for sustainable manufacturing.

- Advanced Material Innovations – Pigs made from self-cleaning and ultra-hygienic materials for improved safety and performance.

With these advancements, sanitary pigging technology will continue to revolutionize liquid processing industries.

Conclusion

A sanitary pigging system is an essential technology for industries that require high hygiene standards, efficient product recovery, and reduced operational costs. By ensuring contamination-free pipeline cleaning and minimizing waste, sanitary pigging systems help manufacturers improve efficiency, maintain regulatory compliance, and enhance sustainability. As advancements in automation and smart monitoring continue, the future of sanitary pigging technology promises even greater improvements in efficiency and cost-effectiveness. Businesses that invest in this innovative system will benefit from improved production processes and long-term savings, making it a valuable addition to any liquid processing operation.